- 客服QQ

-

客服QQ

客服QQ

- 咨詢熱(rè)線

- 15390099989

- 028-36066216

1. Overview

Silane crosslinking low smoke halogen-free flame retardant polyolefin wire/cable material is made by modified polyolefin resin as the main raw material, adding flame retardant agent, stabilizer, eliminate smoke agent, lubricant additives, prepared by mixing, extruding and granulating. It is used to replace the irradiation crosslinking low smoke halogen-free flame retardant material which is current widely used on the market.This product is more convenient and lower cost than the irradiation crosslinking low smoke halogen-free material. It has wide processing temperature range,good processingperformance, convenient operation, and excellent performance.

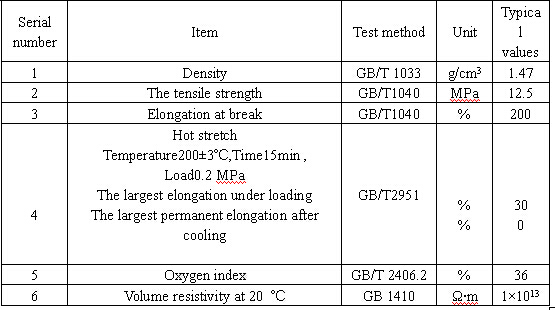

2. Properties

3. Method of use

3.1 Mixing proportion

Mixing material A with material B according to the ratio of 2:1 beforeextruding.

3.2 Extrusion process

This material is suitable for most of the extrusion equipment.

Recommended parameters and process temperature as follows, for your reference.

3.3 Temperature setting

The extruder:160±5℃,170±5℃,185±5℃,195±5℃ Stepwise temperature Settings

Die head :190℃±5℃

The material temperature :195±5℃

3.4 Crosslinking conditions

The wire/cable can be crosslinked after immersed in hot water or exposure to low pressure steam bath, according to 92 ℃, 8 hr for reference. The crosslinking conditions should be adjusted according to the wire/cable diameter and thickness.

4. Attentions

The material A can not be used if the package bag is broken.

During procession, the mixture of material A and B by 2:1 ratio should be used within 4 h, and far away from water.

This material should not stay in the extruder more than 15 min,.

Suggest using polyolefin material to clean the extruder after process.

Cleaning is necessary when the extrusion product appearing crosslinking in advance .

5. Packaging

This product is packaged by the aluminum foil moisture-proof bags. Material A and B are packaged separated .

6. Transportation and storage

This product should not be damped and mechanical damaged during transportation.

This product should be stored in a clean, cool, dry and ventilated warehouse.

Time limit for the storage from the date of production is six months.

Sichuan xincheng new material technology co., LTD

Tel: 0086-28-36066216

Fax: 0086-28-36066206

Http: //www.xcxcl.com

Add: Shigao Economic Development Zone, Renshou. Sichuan Province, China

客服QQ

客服QQ